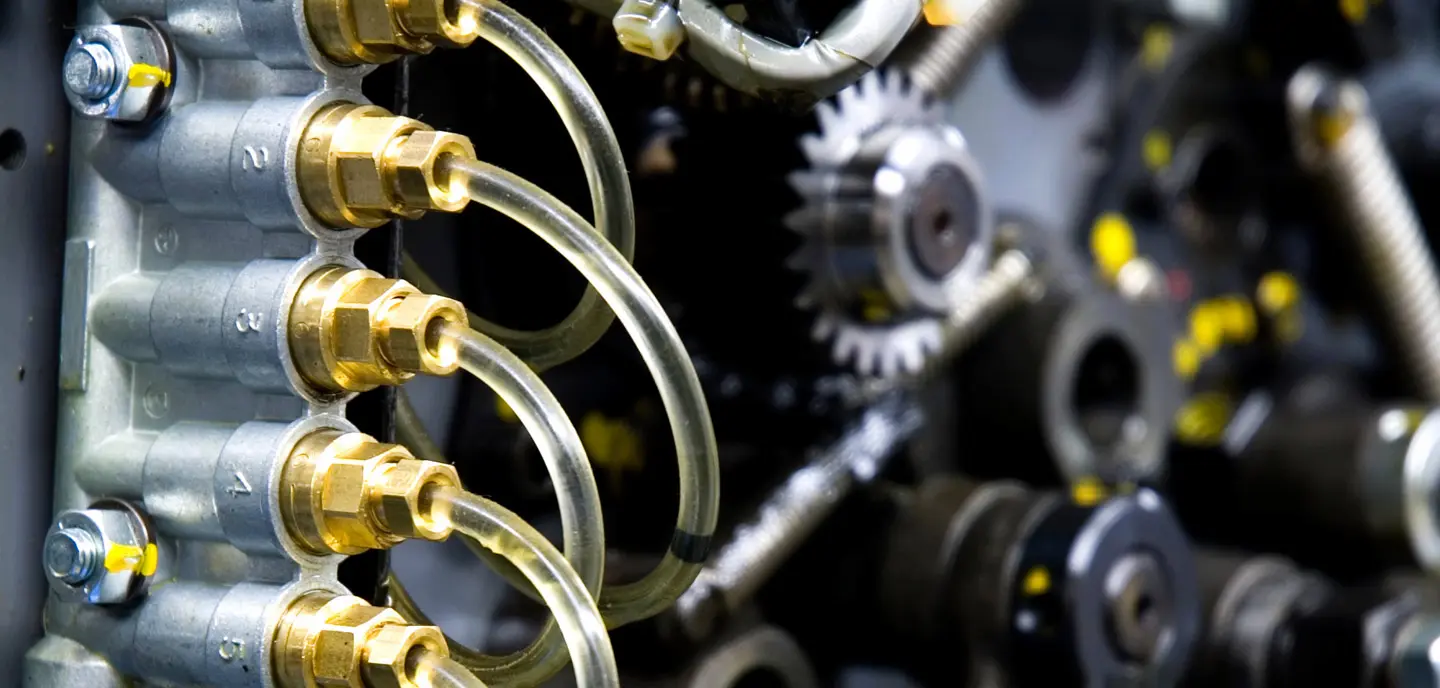

Lubrication systems used to supply lubricant to various application points on machines or equipment. They are widely used in industrial applications, where it is necessary to provide lubrication to multiple components in an efficient and controlled manner.

In these systems, there are two main lubricant distribution lines: the main line and the return line. The main line is responsible for transporting lubricant from the lubrication pump to the distributors, while the return line takes excess unused lubricant back to the pump. This bidirectional flow of lubricant allows for more precise control of the amount of lubricant delivered to each application point.

Centralized dual-line systems offer several advantages. They allow precise and controlled distribution of the lubricant, ensuring that each point of application receives the appropriate amount. Furthermore, these systems are capable of handling long distribution distances and high lubrication demands at different points, ensuring efficient lubrication throughout the system.

Another advantage of centralized dual-line systems is the ability to monitor and control lubrication. Some systems have devices that allow checking the amount of lubricant supplied at each application point. This helps identify lubrication problems and allows adjustments to ensure proper lubrication.